Paul "Scott" – CEO and Co-Founder

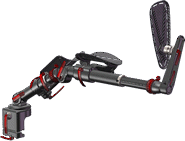

Scott has provided product development and engineering expertise to a diverse array of industries for over 15 years with the majority of his time

being spent on medical device projects. His extensive background in manufacturing provides him with the skills necessary to design products that

are highly optimized for manufacturing and assembly, and to create quality proof-of-concept prototypes. Scott has a passion for integrating both

techniques and engineering fundamentals into the products he

develops, yielding designs that incorporate aesthetically appealing form, ,

and flawless function. Scott studied at

California Polytechnic University, San Luis Obispo.

Scott has provided product development and engineering expertise to a diverse array of industries for over 15 years with the majority of his time

being spent on medical device projects. His extensive background in manufacturing provides him with the skills necessary to design products that

are highly optimized for manufacturing and assembly, and to create quality proof-of-concept prototypes. Scott has a passion for integrating both

techniques and engineering fundamentals into the products he

develops, yielding designs that incorporate aesthetically appealing form, ,

and flawless function. Scott studied at

California Polytechnic University, San Luis Obispo.

Rich Anderson – President and Co-Founder

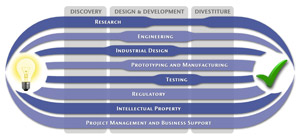

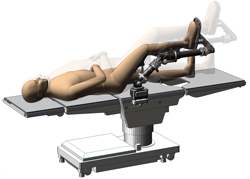

Rich has a broad background in medical device company operations coupled with

and regulatory experience. He has successfully navigated

FDA and ISO audits and has played a pivotal role in submitting medical devices for 510(k) approval as well as maintaining

for medical devices. His operations,

manufacturing, and project management background provide a wealth of knowledge that will improve the success of all projects. His extensive network

of medical device manufacturers ensures that your product will take advantage of the newest advancements in medical device manufacturing. Rich

studied at the University of California at Davis.

Rich has a broad background in medical device company operations coupled with

and regulatory experience. He has successfully navigated

FDA and ISO audits and has played a pivotal role in submitting medical devices for 510(k) approval as well as maintaining

for medical devices. His operations,

manufacturing, and project management background provide a wealth of knowledge that will improve the success of all projects. His extensive network

of medical device manufacturers ensures that your product will take advantage of the newest advancements in medical device manufacturing. Rich

studied at the University of California at Davis.

Sterling Grover – VP Manufacturing Engineering

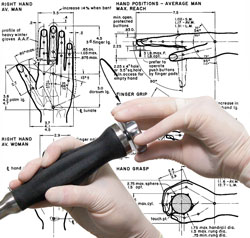

Sterling has

over 30 years of hands-on manufacturing and

experience in a broad array of industries, including , aerospace,

and military. Throughout his career, he has championed the cause for continuous improvement, improving manufacturing processes, optimizing

product manufacturability, and reducing production costs. He excels at analyzing and troubleshooting manufacturing processes through the use

of engineering tools, methods, and techniques; re-engineering processes to optimize product flow, reducing variation, and streamlining operations.

His experience also includes establishing approved vendors, developing assembly processes, training technicians, and installing comprehensive

manufacturing test plans. Sterling has

over 30 years of hands-on manufacturing and

experience in a broad array of industries, including , aerospace,

and military. Throughout his career, he has championed the cause for continuous improvement, improving manufacturing processes, optimizing

product manufacturability, and reducing production costs. He excels at analyzing and troubleshooting manufacturing processes through the use

of engineering tools, methods, and techniques; re-engineering processes to optimize product flow, reducing variation, and streamlining operations.

His experience also includes establishing approved vendors, developing assembly processes, training technicians, and installing comprehensive

manufacturing test plans.

|